Diaphragm Walls

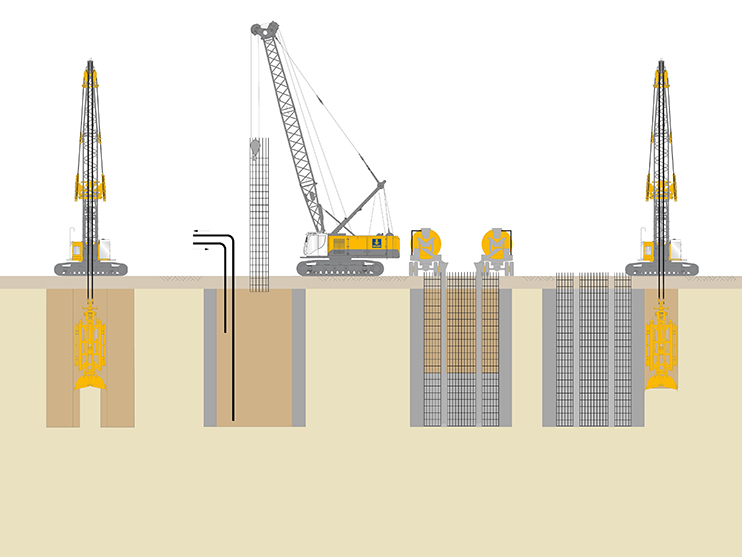

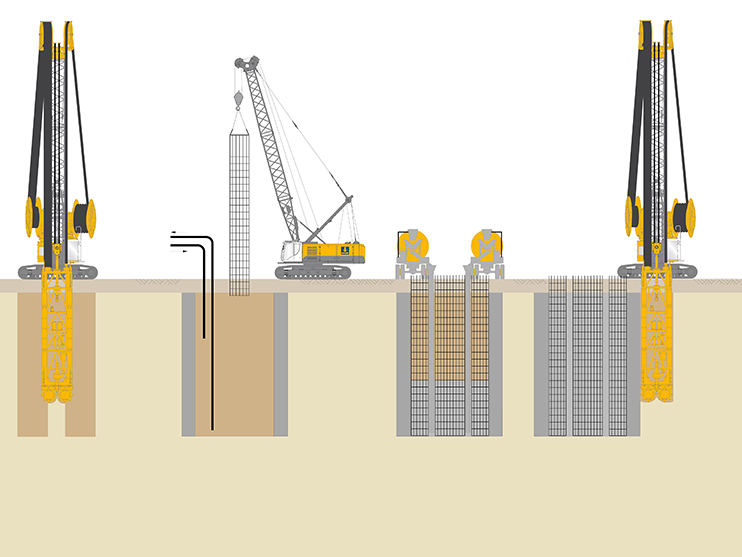

Diaphragm walls serve a structural and/or sealing function and can be used both as a cut-off wall for a dam or excavation pit or as foundation for or to encapsulate a building. They are constructed as concrete or reinforced concrete walls from the ground surface, are considered highly resistant to deformation and virtually impermeable to water. It is excavated in sections with duty-cycle cranes with appropri-ate diaphragm wall grabs or cutters using a supporting fluid between prefabricated guide walls, which serve in particular as a guide for the extraction tool, facilitate support liquid level fluctuations and absorb loads from reinforcements or joint elements. After the final depth is reached, the support liquid is recycled.

n addition, temporary or permanent joint systems can be inserted into the trench, and reinforcement cages can be installed. It is then concreted. As part of the excavation of the adjacent segment, the temporary joint systems are removed for further use. Alternatively, diaphragm walls can also be implemented using the single-phase method. In this case, a binding agent suspension that hardens over time is used as a support liquid. When this method is used, additional sheet piles, supports or prefabricated concrete components can be inserted into the fresh suspension as structural elements, so that the resulting cut-off walls can also perform structural functions.

Types of Construction Method

To excavate the diaphragm, two different grab systems are available, which are suitable for regular wall thicknesses of 600 mm to 1,500 mm. The grab is lowered into the diaphragm and the soil is removed intermittently. Larger blocks or formations of rocks are broken, removed or displaced using modified grabs or heavy-duty chisels. Measuring systems can be installed to prove the verticality.

With mechanical grabs a roller system drives the shovels. In order to increase the clo-sing force, the closing cable is reeved 5 to 8 times. Hydraulic grabs work with a hydraulic cylinder. They have a very high closing force and work with less noise and vibrations than mechanical grabs.

Cutters are used to produce diaphragm walls with thicknesses of 640 mm to 2,300 mm. As they deliver excavation conti-nuously, they are particularly suitable for depths over 40 m. Trench cutters work with two opposing rotating cutter wheels, which, depending on the design, are suitable for a wide range of soil strata, even including the hardest of rocks. The soil material is cut, crushed, mixed with suspension by the wheel rotation, and delivered to the surface via a suction pump. Hydraulic flaps control the cutters in the x and y direction, the penetration depth and speed are regulated via the load from the cutting frame.